ウォームギヤではなぜ「焼き付き」が起こるのでしょうか?

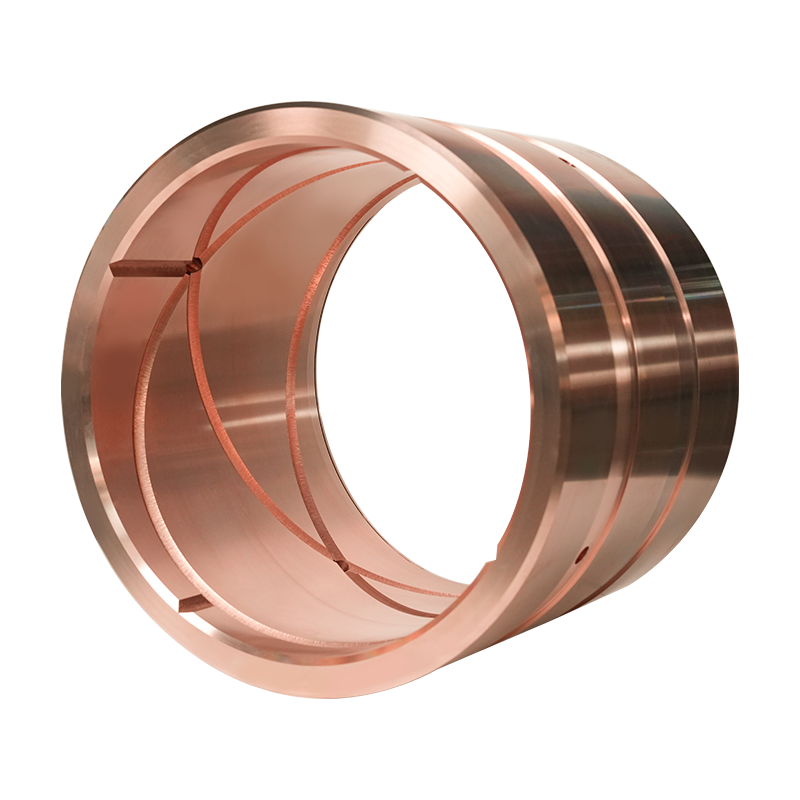

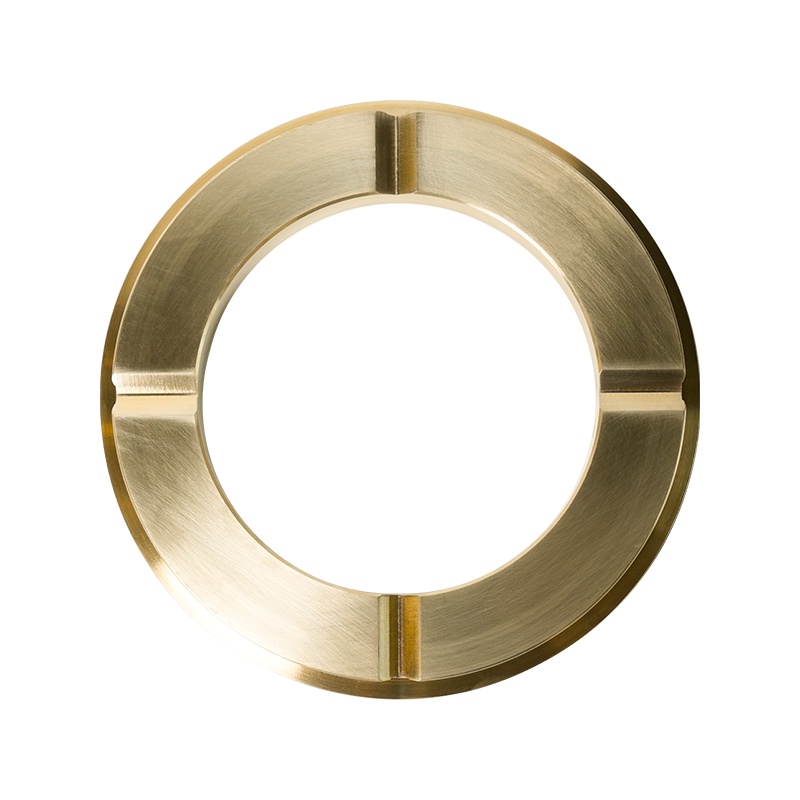

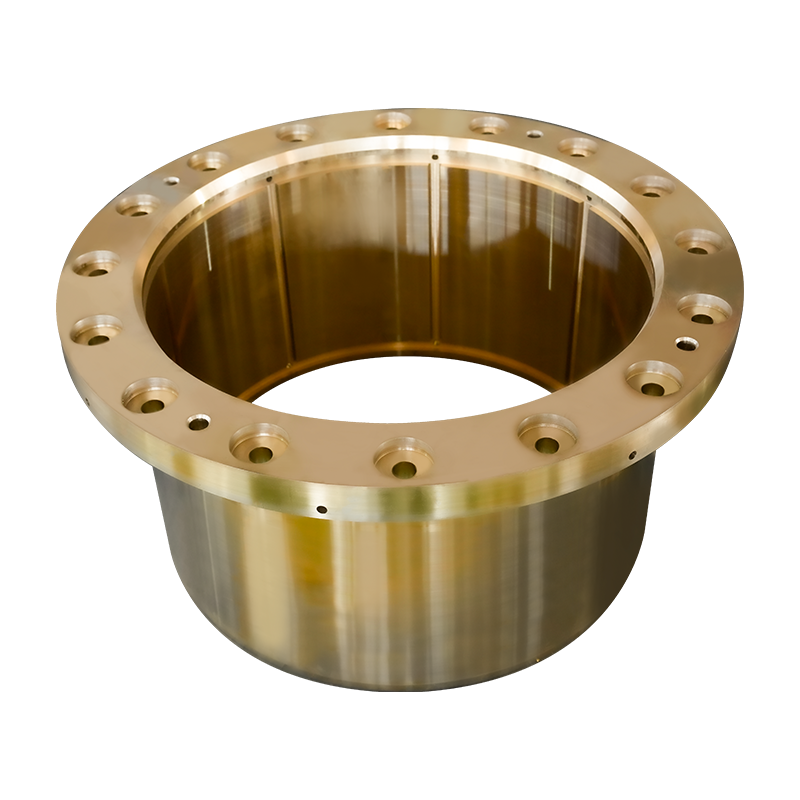

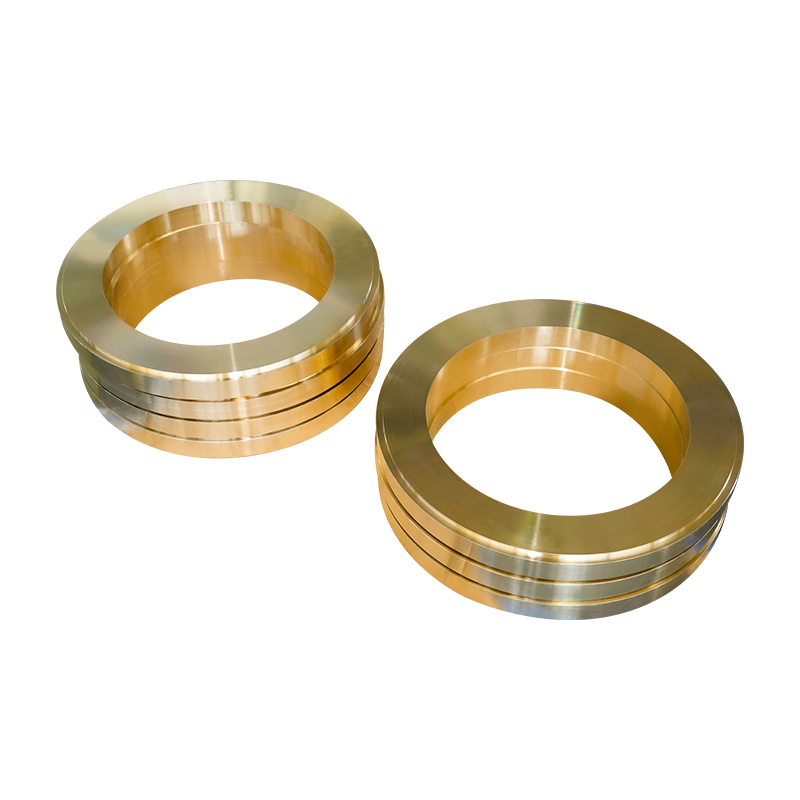

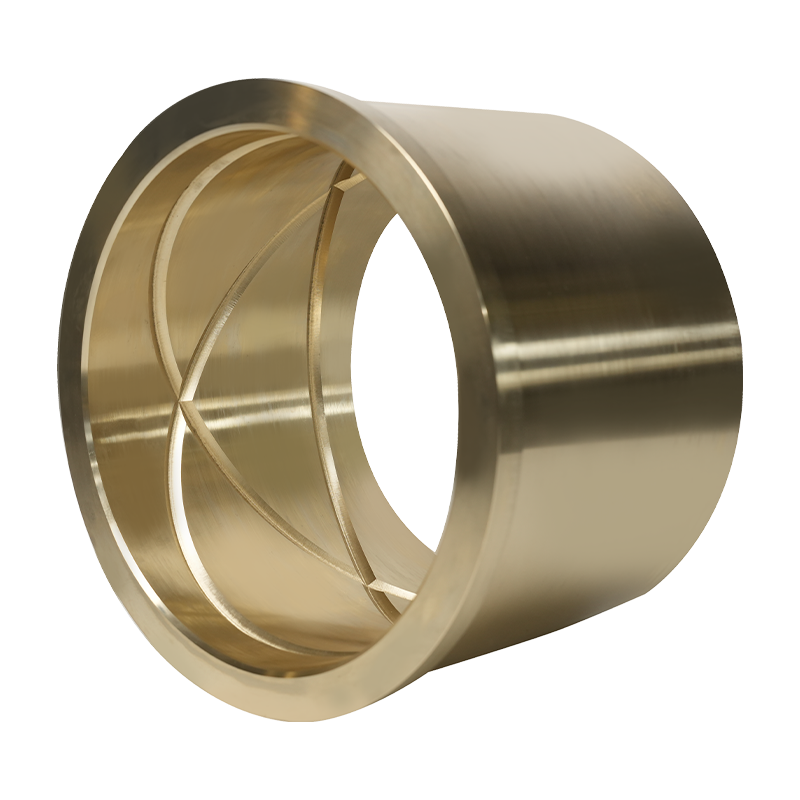

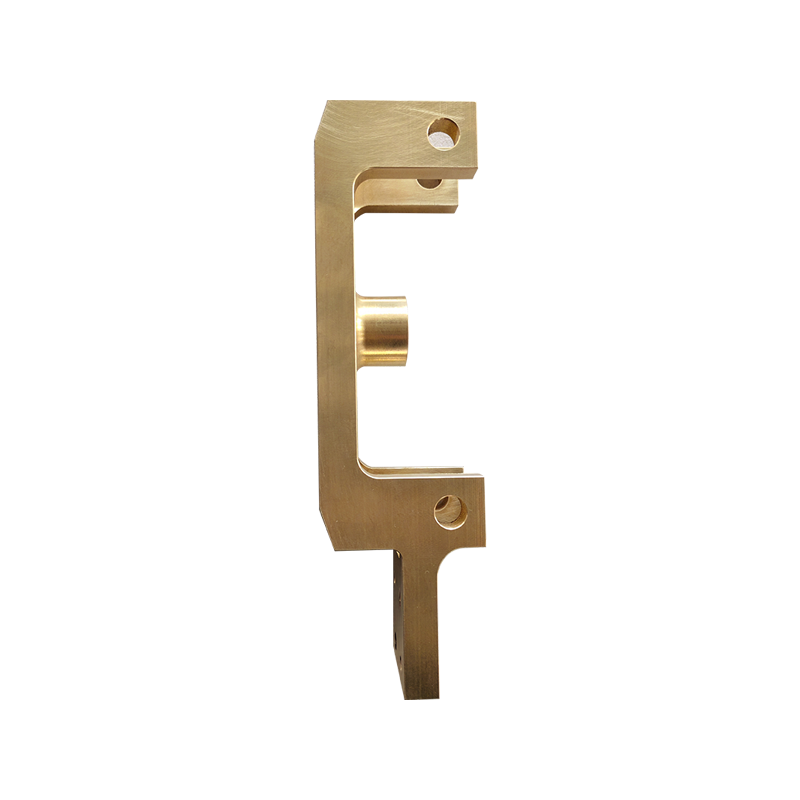

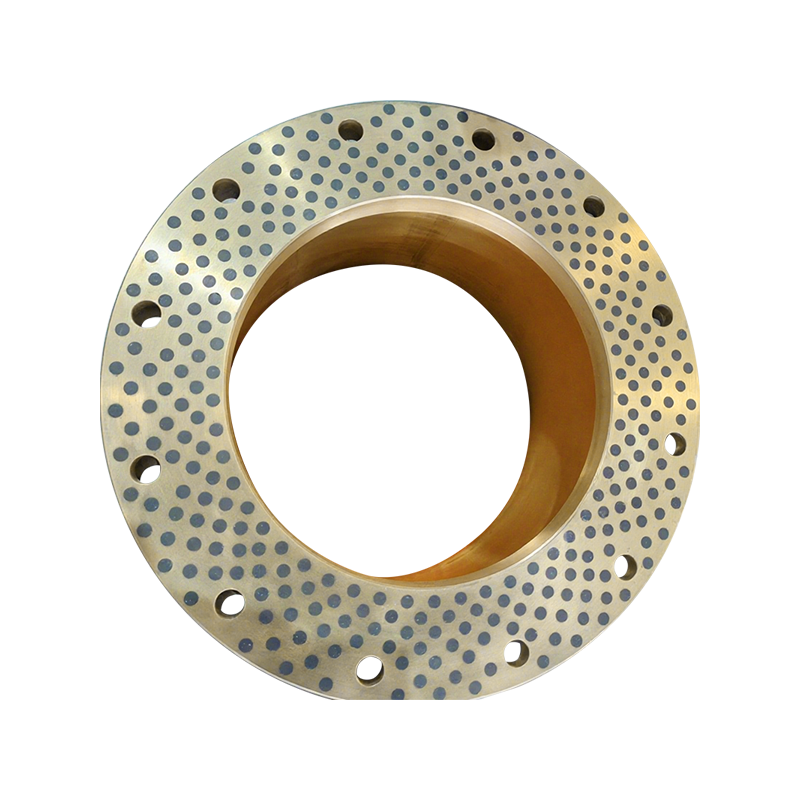

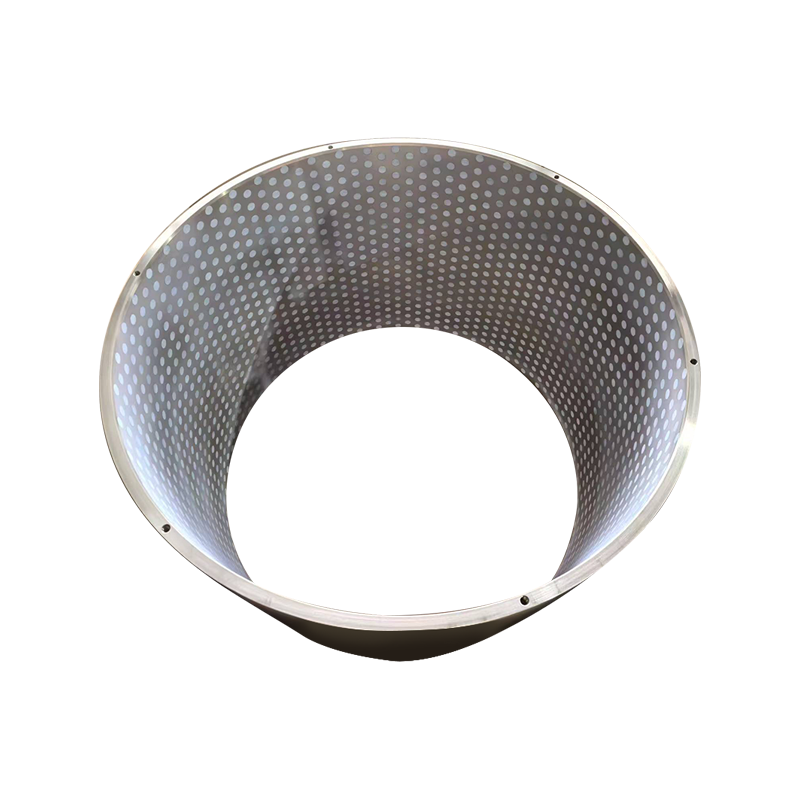

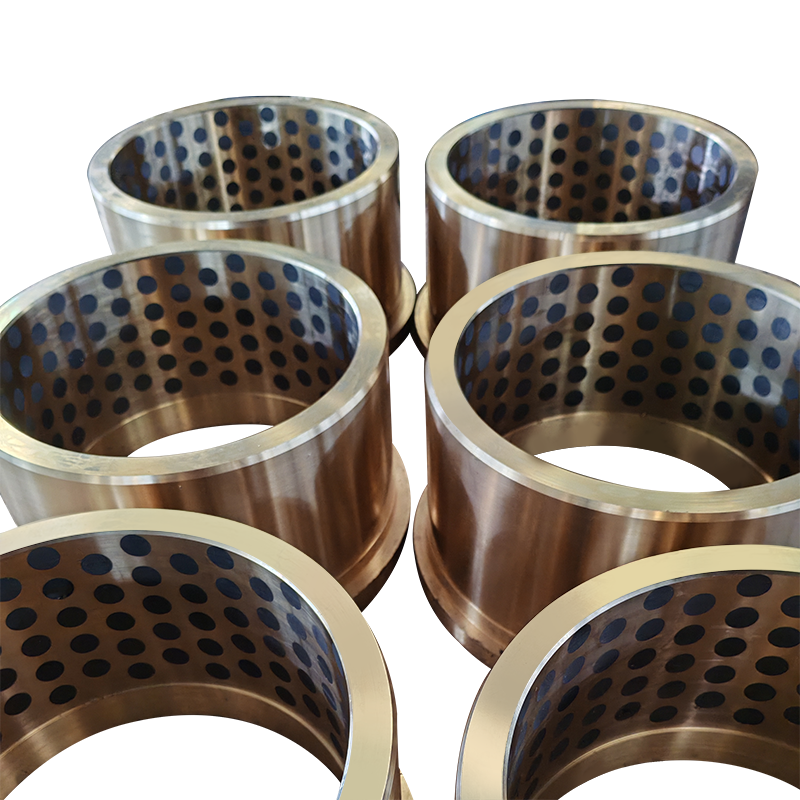

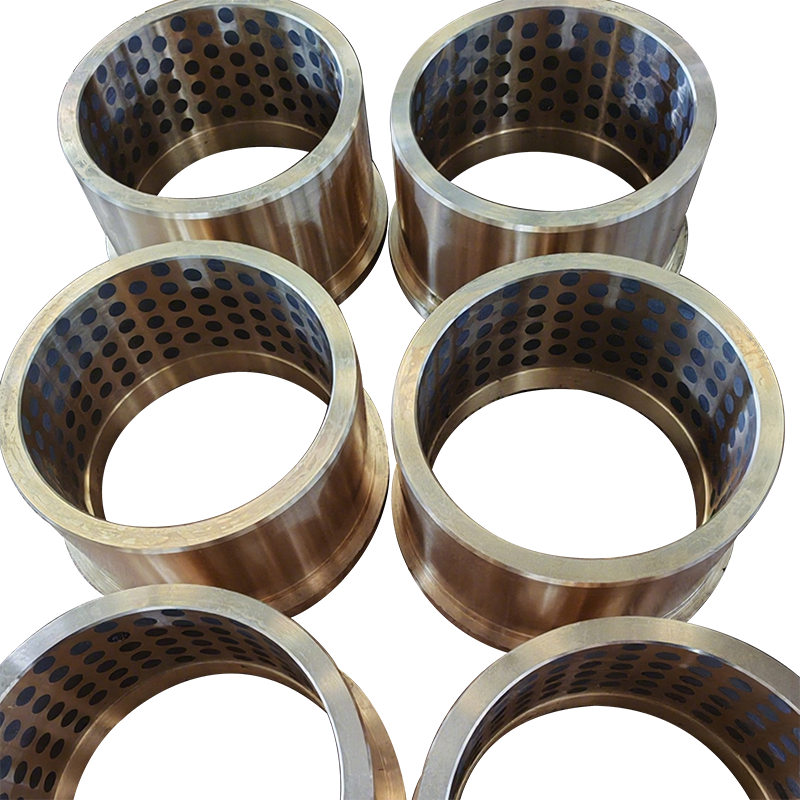

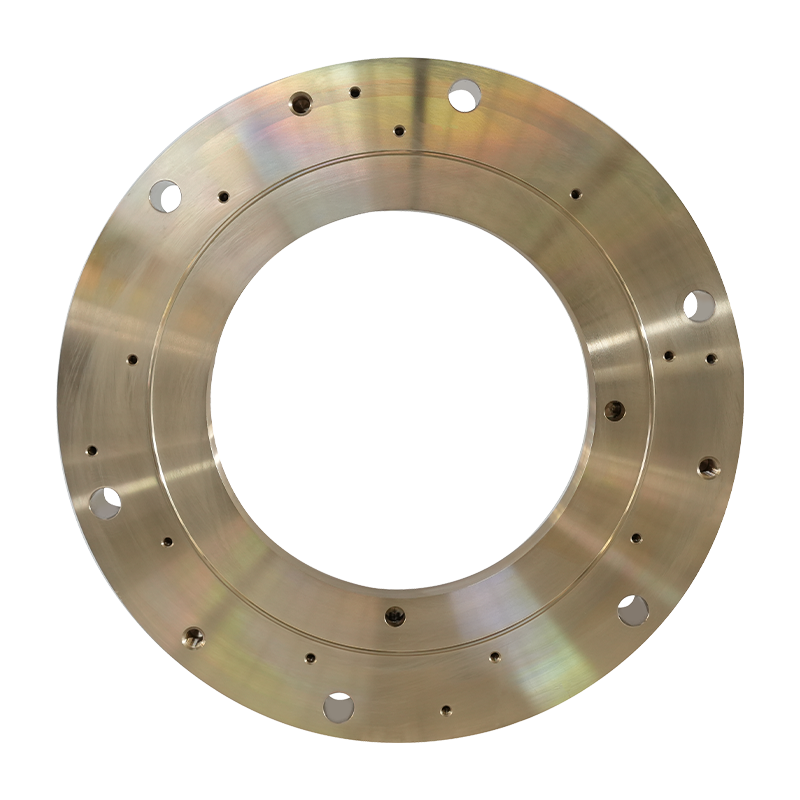

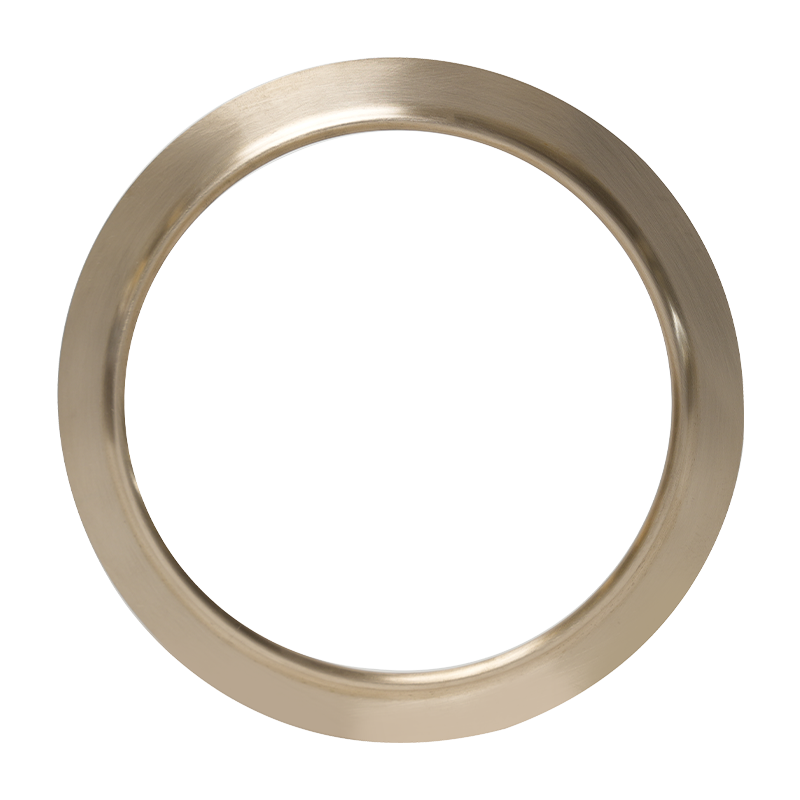

「固着」とは、接触面が損傷する重大な不具合を指します。 ウォームギア 障害後にワームがくっつき、送信が一時的に停止します。この現象は伝送効率と機器の安全性に重大な影響を与え、通常は次の重要な要因によって引き起こされます。 潤滑不良と油膜破壊 ウォーム ギア ドライブは潤滑油膜に大きく依存します。潤滑システムの故障やグリースの粘度の不一致(低温環境下で通常のグリースを使用した場合など)では、ウォームギヤとウォームの接触面に十分な厚い動圧油膜を形成できなくなります。油膜が剥がれると金属面が直接接触するようになり、摩擦が急激に増加し、局部の温度が急激に上昇して固着が発生します。 材料の軟化につながる過度の温度 潤滑油膜が消失したり、潤滑油膜が切れたりすると、ウォームギヤとウォームの接触温度が急激に上昇します。高温によりウォームギアの歯の表面の金属が軟化または焼きなまされ、金属がウォームに付着しやすくなり、固着が発生します。 材料の硬度と表面粗さの不一致 通常、ウォーム ギアの材質はより柔らかく (銅合金など)、ウォームの材質はより硬いです。ウォームギヤの表面硬度が不足したり、表面粗さが大きすぎると、高負荷時にウォームギヤ歯に孔食や摩耗が発生しやすくなり、高温高圧下で金属固着が発生します。このため、材料の硬度と表面仕上げを向上させることが凝着を防ぐ重要な対策となります。 異物による物理的損傷 接着は主に熱接着現象ですが、不純物 (溶接スラグ、鉄やすり、その他の硬質粒子など) による物理的衝撃により油膜が損傷し、局所的な損傷が発生し、熱接着が悪化する可能性があります。

続きを読む

English

English 日本語

日本語 русский

русский Deutsch

Deutsch